Water reuse in paper mills

■Technology R&D Background

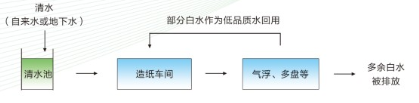

At present, many household paper mills have problems of excess white water and unbalanced water volume in the workshop water circulation system. The existing paper machine white water is collected by the water collecting device such as air flotation and multi-disc. Most of the water is collected after simple treatment. At the same time, there is a part of the unbalanced excess water, which is directly discharged to the external sewage pipe network or the ditch river. Invisibly caused a waste of water resources.

With the development of the domestic environmental protection industry and the awakening of the national environmental protection awareness in recent years, as well as the government's efforts to strengthen the control of water resources utilization and the continuous improvement of pollution discharge standards, the reuse of water reuse has gradually developed in the paper industry.

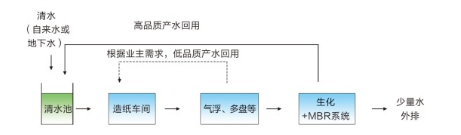

After years of exploration of the sewage treatment technology in the paper industry, our company introduced a “biochemical + MBR” sewage treatment program to turn paper white water into reusable water. It has brought obvious economic benefits to the enterprise and created good environmental benefits for the protection and rational use of water resources.

■Technology

Original process map

Process flow after transfo

■Technical advantages

○ Reduce the amount of water and water for the company.

Less groundwater or tap water saves water and reduces the cost of water withdrawal.

○ Reduced the cost of corporate sewage.

The effluent from the sewage treatment system returns to the workshop for reuse, which reduces the amount of water discharged from the enterprise sewage and saves the cost of sewage disposal.

○ The effluent water quality is excellent.

The escape system uses MBR with a pore size of 0.01~0.1 microns, which can intercept most of the bacteria, colloids and other substances. The suspended matter is almost zero, and the effluent is extremely clear and transparent. In addition to being recyclable, it can also meet the discharge requirements for discharge into pipe networks and rivers, and solve the problem of unqualified drainage for some enterprises.

○ System operating costs are low.

The running system adopts PLC control, which can realize full-automatic operation without special personnel. The daily operating expenses are mainly electricity and a small amount of pharmaceutical fees. The processing cost per ton of water is only 0.6~0.8 yuan.

○Intelligent plant management system

The intelligent plant management system consists of field equipment, regional monitoring, PLC control system and central control system. It can realize remote monitoring of equipment operation status and operating parameters of sewage treatment station, remotely view real-time photos or videos of sewage treatment station, abnormal operation of equipment, automatic alarm of pressure level over-limit, remote control of lifting pump, production pump, fan and other equipment Control, statistically analyze and analyze the processing capacity and effect of the sewage treatment station, remotely update the equipment program, and obtain on-site data analysis problems.

The informrmationation is released through the Internet of Things, and the multi-machine information sharing of terminal devices such as collection and computer is realized. At the same time, commands can be issued through the terminal device to control the operation of the field device. The intelligent plant management system has greatly improved the management level of the sewage treatment system.

CONTACT US

Internal trade department:086 312-3157598 +86 15033298080

International trade department: 086 312-8913138

Procurement Department Phone:13603126093

E-mail:hbzhile@163.com

Address:2162-8 South Second Ring Road, Baoding City, Hebei Province

Web:www.hbzhile.cn