Energy-saving integrated sewage treatment equipment

First, research and development background

Zhile energy-saving integrated sewage treatment equipment is a new type of distributed sewage that has been successfully developed by our company and Mitsubishi in cooperation with the status quo of sewage treatment in China's villages and towns, integrating energy-saving aeration and automation control technology based on traditional MBR technology. Processing equipment. In recent years, it has been widely used in sewage treatment projects. The effluent quality of the equipment can reach the maximum allowable discharge standard of pollutants specified in Grade A of the Municipal Wastewater Treatment Plant Pollutant Discharge Standard GB18918-2002, and the dissolved oxygen, COD, NH4-N, and fecal coliforms The other indicators are in line with the relevant indicators of Class IV water in the surface water quality standard of GB3838-2002.

Second, the equipment structure

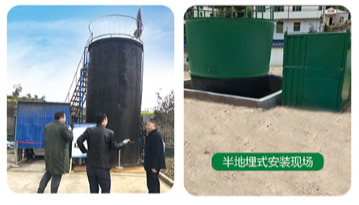

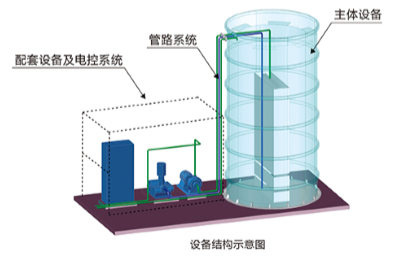

Zhile energy-saving integrated sewage treatment equipment has lower energy consumption and smaller footprint due to its unique equipment structure and advanced MBR membrane components. The main structure of the device adopts a vertical design, and the inner part of the cylinder is divided into different processing units such as oxygen deficiency and aerobic, and the MBR membrane module is placed in the aerobic tank. The supporting equipment and electrical control system are placed in the equipment room. This series of products are modular units. According to the design drawings, they are welded and assembled in the factory, and the delivery speed is fast.

Note: According to local regulations, the specific conditions of the water quality of the inlet and outlet water, this product may be added with other ancillary structures or equipment.

Third, equipment technical characteristics

●Optimization of product structure

1 Unique vertical structure design can save 1/3~1/2 of the floor space compared with the traditional horizontal integrated MBR equipment, and solve the problem of high transportation limit.

2 Optimized product structure, saving backflow pump and reducing equipment running power.

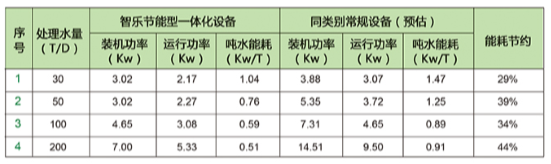

3 Due to the improvement of effective water depth, Mitsubishi's newly developed 40 square meters/piece of large square film can be used. The overall operation process of the equipment can reduce the energy consumption by 25%~45% compared with other products of the same category.

●The system has advanced technology, strong resistance to water quality impact, less mud discharge, and covers an area and low construction cost.

Due to the use of the MBR system, the sludge concentration and volumetric load can be greatly improved, so when the influent water quality suddenly changes, the overall system has a certain buffering capacity. At the same time, the high-efficiency interception of the membrane increases the sludge age of the whole system, so the amount of excess sludge generated is small, and basically no sludge is required. At the same time, the vertical structure not only saves the floor space of the second settling tank, but also saves 1/2 of the land on the basis of the traditional integrated equipment.

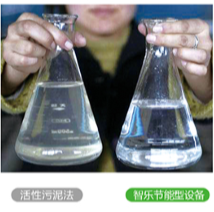

●The water quality is excellent and extremely clear.

The water quality of this series of products can not only meet the Class A standard of GB18918-2002 “Emission Standards for Pollutants in Urban Sewage Treatment Plants”, but also dissolve oxygen, COD, NH4-N and fecal coliforms when the operation is ideal. The number of indicators can reach the relevant indicators of surface class IV water. In the water-deficient areas, the water produced by this series of sewage treatment equipment can directly enter the RO reverse osmosis system.

When the effluent standard is strictly required to meet the surface water quality standards of Class IV, it must be operated by professionals to create good living environment conditions for microorganisms by controlling factors such as nutrients, temperature, pH, dissolved oxygen and toxic and hazardous substances (if necessary, Can be supplemented by other reasonable processes).

The system is simple and easy to understand, and the equipment maintenance cost is low.

The process flow of this series is simple and easy to understand. By adding various control conditions, the operation manager can quickly understand the whole process flow and equipment operation.

The electrical control system is mainly divided into PLC centralized control and common control, which can realize the switching of manual automatic control. When the system is in normal operation, no matter what kind of control method, no special person is required to perform the duties. Ordinary control, daily arrangements for personnel to go to the site for a simple tour. PLC control, system one-button start and stop, easy to operate, and easy to adjust operating parameters, control level is higher.

Intelligent factory management system

According to the needs of users, our company can provide supporting facilities and technical services for the intelligent management system of the supporting sewage treatment plant (or other enterprises and institutions), popularize and upgrade the automatic control system of the traditional sewage treatment plant, and improve the intelligence of the sewage treatment system. Management level.

The intelligent plant management system consists of field equipment, regional monitoring system, PLC control system and central control system. On-site processing of water, water quality and other data information, monitoring information and equipment operation, etc., collected by instruments, monitors, etc., transmitted to the regional monitoring system and PLC control system for sorting and analysis, and then through the Internet of Things for information Released to realize multi-machine information sharing of mobile devices, computers and other terminal devices. At the same time, commands can be issued through the terminal device to control the operation of the field device. The intelligent plant management system has greatly improved the management level of the sewage treatment system.

Fourth, the application field

Five, equipment size

CONTACT US

Internal trade department:086 312-3157598 +86 15033298080

International trade department: 086 312-8913138

Procurement Department Phone:13603126093

E-mail:hbzhile@163.com

Address:2162-8 South Second Ring Road, Baoding City, Hebei Province

Web:www.hbzhile.cn